Tin Plate Lite—System-matched and guaranteed to run on GED Intercept® Spacer Frame machines

Tin Plate Lite® was designed in conjunction with GED as an improvement to standard Tin Plate Steel Coil on the Intercept roll former. Tin Plate Lite is designed with a specific formulation for improved equipment performance and overall lower operating costs.

No equipment adjustments are needed to run Tin Plate Lite. Moreover, Tin Plate Lite reduces build-up by 90%, which reduces overall maintenance and per unit manufacturing costs.

Tin Plate Lite is the new alternative steel coil for your roll former frame building machinery.

User Benefits

- 90% less build-up on GED Intercept roll formers

- No equipment adjustments needed

- Reduced labor & production costs

- Approved by four major sealant manufacturers

Leading Edge Benefits

- System-matched GED approved material

- All prime material

- Stocked sizes across North America

- Competitive pricing

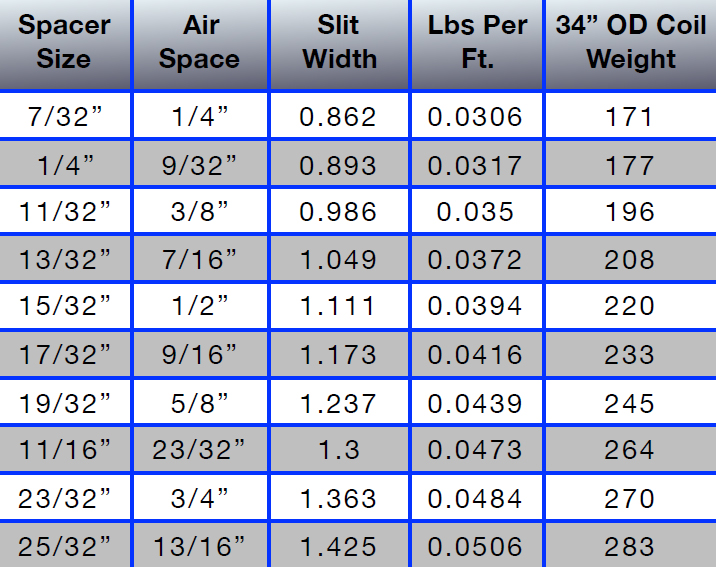

Technical Specifications

- Compliances: GED Intercept, H.B.Fuller, PPG, & Kommerling

- Architectural Testing: ASTM E2188 E2190 IG Durability

- Material Thickness: 0.0105″ + / – 0.0005

- Weight: 95# per base box (0.0105″) thickness

- Temper: T-4 (AIM 58-64 RW 90-t)

- Finish: 5# finish (AIM 45 + / – 15 micro-inches)

- Oil Level: ATBC oil level 1 with minimum chemtreat -CDC-5 450 + / – 100 microgram / square ft

- Cut Slit Width Tolerance: + 0.000″ / – 0.005″ burr-free edge

- Coil Core Size I.D.: 16″

- Coil O.D.: 36″ maximum

- Coil Weight of 1″ Wide: 225# (approximate)

- Linear Feet / Coil: 6400 ft (approximate)

Technical Data Sheet on Tin Plate Lite